Solid Dowel Pins

Solid Dowel pins are cylindrical press-fit fasteners that provide precision solutions for a variety of fastening applications. They are used in the same manner as Grooved Pins when highly accurate location is required. Once a dowel pin is inserted into a reamed hole, it is then held in place using radial force. This ensures a secure and lasting hold.

Dowel pins can be measured in millimeters or in inches. This ensures consistency for industrial applications. Dowel pins come in a wide range of materials, including wood, stainless steel, alloy steel, and zinc-plated steel. Dowel pins are manufactured in standard diameters, and can also be made in custom diameters to meet special needs. If you do not find a dowel pin in the size you need, a precision dowel pin can be custom made for you.

Common Uses

Because dowel pins allow two components to be joined together safely and securely, they can be used across a wide variety of industries. They are frequently utilized in furniture making and cabinetry, as they provide a secure join without altering the shape or impacting the frame of the finished piece. Construction and engineering industries similarly rely on dowels to keep machinery in alignment, hold parts together, and finish work. The automotive, aerospace, and manufacturing industries rely on dowel pins to join different components of machines together to ensure a proper alignment. All of these industries require components that are guaranteed to perform and uniform in size.

Precision Dowel Pins

Precision Dowel pins come in many finishes, sizes, and types, allowing them to be used for nearly any fastening need across industries. When precision, ease of use, and efficiency are needed, dowel pins are an excellent and cost-effective choice. Precision dowels pins are the best choice for press fits.

DRIV-LOK’S product engineers provide technical assistance for customers to ensure that precision dowels are manufactured to the appropriate specifications. They also help select the appropriate material and diameter size for the dowel based upon the materials used and depth required.

Custom Dowel Pins

DRIV-LOK offers several types of custom dowel pins, including the following:

- Grooved Dowel Pins – Grooved dowel pins, also known as fluted dowel pins, have threads along the sides that provide texture. These are commonly used as pivots or locking devices when there is not a high end load in use. These are available in a full range of sizes. To know more click here.

- Solid Dowel Pins – Solid dowel pins are an alternative to grooved pins, but have straight sides instead of threaded sides. They are commonly used across a range of applications when accuracy is required.

- Vent Dowel Pins – Vent dowel pins closely resemble solid dowels, with the addition of three helical grooves that run along the diameter. The grooves help to relieve air locks when solid dowels are placed in a round hole.

Each of these can be custom made in our full range of sizes and materials, ensuring the perfect fit for any application.

Why DRIV-LOK

DRIV-LOK is dedicated to providing customized service and delivering only the highest quality custom and precision dowel pins. We have over 70 years of experience in the industry and are widely recognized as a leading manufacturer of American-made press-fit fasteners and joining components. We hold certifications from the ISO that demonstrate that our custom made dowel pins conform to industry standards, and that we follow industry best practices for the highest quality. We have developed a reputation for providing reliable products and engineering custom solutions for our customers.

Because our engineers work directly with clients to ensure that clients get the right project to meet their needs, the quality and integrity of the finished product is assured. Our engineers have a highly comprehensive understanding of the joining and press-fitting process, which enables us to provide our customers with unique products for a full range of needs. We have the capacity to fulfill orders quickly and accurately, and have developed a reputation for ingenuity, dedication and service. Get started today, request a free quote for specific product pricing.

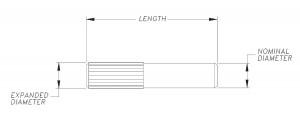

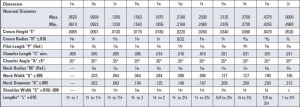

Description

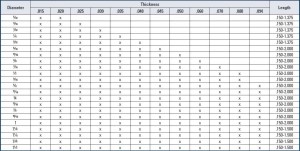

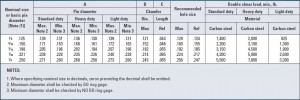

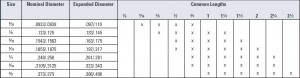

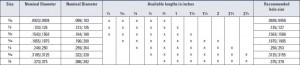

Plain pins are solid cylindrical pins which have a cold drawn finish. Plain pins with diameters up to 1/8″ have a tolerance of +.000/-.001 in. and diameters 1/8″ and over have a tolerance of +.000/-.002 in.Dowels are solid cylindrical pins which have a centerless ground finish with total precision tolerances.

All plain pins and dowels are special-order items. Various materials, diameters, lengths, end configurations, heat treatment, and finishes are available.

DRIV-LOK’S engineering department will work with customers to provide technical assistance.

Function

Plain and dowel pins are held in place by interference created around the entire pin circumference when it is

pressed into a hole. The insertion, holding, and radial forces generated by these pins are very sensitive to hole diameter variation and usually require the use of a reamed hole.