Split & Seamless Hollow Dowels

Split Hollow Dowel is an excellent cost-saving option not widely offered by other manufacturers. As a result of using less material and eliminating reaming and finishing, the Split Hollow Dowel can save you between 30-40%.

- Excellent retention and ease of assembly – a typical application is where two halves of an assembly are located and bolted together. Also used as spacers or compression limiters

- Available in a variety of materials, finishes and can be heat treated

- Can be auto-inserted

- Style Choices: Straight Gap & Anti-Interlock Gap

Seamless Hollow Dowels are used where a seam is not allowable or desired, such as for custom applications that cannot accept the split format.

- Typically used as locators, spacers or standoff

- Available in a variety of materials and finishes

- Can be heat treated

- Can be auto-inserted

Description

DRIV-LOK’s split hollow dowels are designed and manufactured to provide excellent retention forces and ease of assembly. They can also be auto-inserted.

Split hollow dowels are ideal for use in conjunction with bolts that pass through the center of the dowel after it has been installed. This offers a weight savings over conventional locating dowels, which require separate drilled and reamed holes. The expense and labor involved in providing separate locating dowels and their holes in

assemblies is eliminated. The bolt hole is counterbored on both halves of the assembly. The dowel is then installed into one of the counterbores and used to locate the other half of the assembly. “Split” hollow dowels offer additional cost savings over hollow dowels machined from tube or bar stock.

Function

A DRIV-LOK split hollow dowel is also used as a Compression Limiter to protect plastic from being crushed or yielding past its elastic limit. When properly designed the bolt head or washer will allow proper seating of the bolt to hold the component in place and the compression limiter will absorb the clamping pressure.

Another application of a DRIV-LOK split hollow dowel is when used as a spacer or standoff to space components apart from one another. They have been used over shafts or bolts to give a set distance between component assemblies.

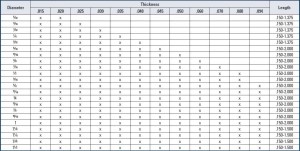

Dimensions

CAD Diagram

Success stories

SITUATION

A leading automotive manufacturer requested engineering assistance from Driv-Lok to solve an assembly problem on one of their transmission lines. The problem was defined as an occasional mis-feed of threaded fasteners during the assembly of a wear plate to the housing. The mis-feed caused the fasteners to fall into the gears and cause failure of the entire assembly. The threaded fastener’s only function was to hold the wear plate to the housing so it could be inverted for assembly completion.

SOLUTION

This application was already using Driv-Lok split hollow dowel pins as a partial holding system. Driv-Lok’s ENGINOMICS team reviewed the situation and added a locking feature to the center of the split hollow dowel, which held the wear plate in place. This feature was then patented under patent #US 7,241,095 B2. This upgrade eliminated the use of the threaded fastener, provided the customer with cost savings, solved the problem, and prevented future defects.

ADVANTAGES

- IMPROVED ASSEMBLY METHODS

- REDUCED COSTS OF OVERALL ASSEMBLY

- ELIMINATION OF ASSEMBLY PROBLEM

- REDUCED NUMBER OF THREADED FASTENERS REQUIRED